In today’s world, where the focus on sustainability and energy efficiency is paramount, heat recovery has emerged as a key solution to reduce energy costs and minimise environmental impact. By recycling waste heat, heat recovery system offers a practical and eco-friendly approach to maximising energy efficiency. This blog post will delve into the significance of heat recovery, its environmental and economic benefits, and the key components of a heat recovery exchanger, how heat recovery ventilation works in different industries etc.

Understanding Heat Recovery and Its Significance

Heat recovery represents a pivotal strategy in the pursuit of sustainable energy management, enabling the capture and reuse of heat that would typically dissipate into the environment unutilised. This process plays a critical role across many settings, from industrial to residential, capturing excess thermal energy from activities such as manufacturing operations, power generation, and even the daily running of HVAC systems. The essence of heat recovery lies in its dual capacity to significantly diminish energy expenditures and concurrently lower the environmental footprint of operations. It operates under the principle of rechanneling wasted heat for useful purposes, ranging from heating spaces to preheating incoming air or water for various processes.

This makes a compelling case for its integration due to the direct energy savings it offers and highlights its contribution towards mitigating the effects of climate change by reducing the demand for fossil fuel consumption. In doing so, heat recovery systems align closely with global sustainability targets, offering a pragmatic path towards enhancing energy efficiency without compromising operational needs or comfort levels. This technique underscores the broader shift towards more conscientious energy use, where the value of lost energy is recaptured, underpinning efforts to foster a more sustainable and economically viable energy landscape.

The Environmental and Economic Benefits of Heat Recovery Unit

The Environmental and Economic Benefits of Heat Recovery Unit

Investing in heat recovery systems stands at the forefront of fostering a sustainable future, marrying the need for economic prudence with environmental stewardship. Such systems play a crucial role in curtailing reliance on non-renewable energy sources, thereby slashing greenhouse gas emissions—a critical step towards halting the march of climate change. The essence of recycling waste heat not only aligns with the urgent call for cleaner energy practices but also marks a significant stride in the pursuit of green, sustainable growth.

Economically, deploying heat recovery units transforms energy management within organisations, offering a pathway to notable cost reductions. By harnessing thermal energy that would otherwise escape unused, these systems reduce the demand for additional heating or cooling energy, leading to lower operational expenses. The savings from diminished energy requirements can be substantial, offering a compelling case for the initial investment in heat recovery technologies.

Moreover, integrating such units bolsters operational efficiency, further enhancing their economic appeal. Organisations benefit from the dual advantage of contributing to environmental conservation efforts while achieving financial savings, thus embedding sustainability into their operational ethos. This synergy between economic benefits and ecological protection underscores the pivotal role of heat recovery unit in shaping a future where energy efficiency and environmental responsibility go hand in hand.

Key Components of a Heat Recovery Exchanger

At the heart of every efficient heat recovery system lies the heat recovery exchanger, an apparatus designed to facilitate the seamless transfer of heat from one medium to another without direct contact. Central to the operation of a heat recovery exchanger are several pivotal components, each playing a critical role in ensuring the system’s efficiency and reliability. The heat exchanger core is the most vital component where the actual heat transfer occurs, typically constructed from materials that excel in thermal conductivity to maximise heat transfer rates.

Adjacent to the core, the control system serves as the brains of the operation, intelligently regulating fluid flow rates and adjusting operating conditions to maintain efficiency under varying loads. This ensures that the heat exchanger operates at its optimal performance, adapting to the changing needs of the environment it serves.

Supporting components such as pumps and valves work in concert to maintain the fluid flow at precise rates, which is essential for the effective transfer of heat. Filters also play an indispensable role, protecting the system from particulate matter that could impede its functionality or lead to premature wear.

Together, these components form the backbone of a recovery exchanger, each essential to the system’s ability to reclaim energy that would otherwise be lost, thereby contributing significantly to energy conservation efforts and the sustainability of operations across industries.

How Heat Recovery Ventilation Unit Works in Different Industries?

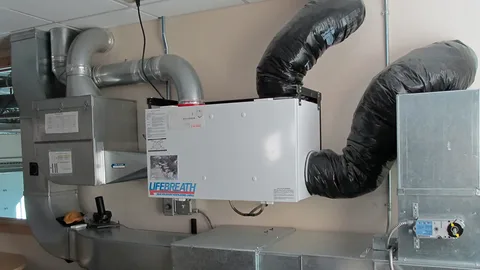

Heat recovery ventilation (HRV) units find their place in diverse sectors, each with unique demands and environments. In manufacturing, where air quality and temperature control are critical, HRV systems are vital in maintaining optimal conditions. These units effectively manage the thermal comfort of large workspaces whilst ensuring the removal of contaminants and stale air, directly contributing to a healthier work environment and enhancing productivity.

With its stringent requirements for hygiene and temperature control, the food processing industry benefits significantly from HRV technology. By providing a constant supply of fresh, filtered air and maintaining precise temperature conditions, HRV units help preserve the quality of perishable goods, extend their shelf life, and compliance with health and safety standards.

Commercial buildings, including offices, retail spaces, and educational institutions, use HRV systems to create comfortable indoor climates for occupants. By balancing indoor air quality and temperature, these units support energy conservation goals and create a more sustainable built environment. The adaptability of Heat Recovery Ventilation Unit to different industries showcases its versatility in contributing to energy efficiency and sustainability across the board, making them an integral component of modern energy management strategies.

Maximising Efficiency with Heat Recovery Ventilation

Several strategies are crucial to ensure heat recovery ventilation systems operate at their peak. Initially, selecting an HRV unit that matches the specific demands of the premises is key. This involves considering the volume of space, the nature of air contaminants if present, and the usual occupancy patterns. Tailoring the system to these variables ensures it’s neither over- nor under-performing, optimising energy use and recovery. Proper installation by qualified professionals is another critical factor.

Incorrect installation can lead to inefficiencies, such as heat loss or inadequate ventilation, negating the system’s potential benefits. Regular maintenance is equally important to sustain efficiency over time. This includes routine checks and cleaning of filters, vents, and heat exchange surfaces to prevent blockages that can impair performance. Integration with other building management systems can further enhance efficiency.

For instance, smart controls can adjust the HRV unit’s operation based on real-time data, such as occupancy levels or air quality, ensuring it operates only when needed and at optimal levels. Implementing these strategies can significantly contribute to the overall energy efficiency of buildings, supporting sustainability objectives while providing a comfortable and healthy indoor environment for occupants.

Overcoming Challenges in Implementing Heat Energy Recovery System

Implementing heat energy recovery system, whilst beneficial in the long run, does encounter initial hurdles. These range from the financial—where the initial outlay can be significant—to operational challenges, including integrating such systems into existing energy frameworks. A pivotal approach to mitigating these challenges lies in comprehensive planning and engagement with expertise in the field. Detailed feasibility studies and cost-benefit analyses can illuminate the path towards a financially viable implementation, ensuring that the investment aligns with long-term savings and efficiency gains.

Educational and training programmes are critical in overcoming technical barriers and equipping personnel with the necessary skills to manage these sophisticated systems effectively. Additionally, leveraging governmental incentives and grants for energy-efficient technologies can alleviate financial constraints, making adopting heat recovery systems more accessible.

Collaboration with experienced engineers and designers during the initial phases can ensure that systems are customised to meet a facility’s specific needs, thereby optimising performance and integration. This tailored approach, alongside a commitment to regular maintenance and updates, can significantly diminish operational challenges, ensuring that heat recovery systems deliver on their promise of enhanced energy efficiency and sustainability.

Future Trends in Heat Recovery Technologies

The horizon of heat recovery technologies is witnessing a swift evolution, underscored by a drive towards greater efficiency, compactness, and smarter operation. Innovations in material science promise to deliver heat exchangers of unprecedented efficiency and reduced size, enabling their integration into a wider range of applications and environments. The advent of intelligent systems equipped with advanced sensors and AI-driven controls is poised to revolutionise how heat recovery units operate. These smart-systems can autonomously adjust to changing environmental conditions and usage patterns, ensuring optimal performance while minimising energy wastage.

Renewable energy sources are becoming increasingly intertwined with heat recovery solutions, offering the prospect of further reducing dependency on fossil fuels and enhancing sustainability. Integrating solar thermal panels, for example, with heat recovery systems is an area ripe for development, providing a renewable source of heat to be recycled and used.

Moreover, the shift towards decentralised energy systems opens new vistas for applying heat recovery technologies. In a future where energy production and consumption are more localised, heat recovery systems could be pivotal in maximising efficiency and sustainability at the community or even individual building level, heralding a more resilient and environmentally friendly approach to energy management.

Conclusion

Heat recovery emerges as a cornerstone in the quest for energy optimisation and environmental stewardship, encapsulating a blend of innovation and practicality for the modern world. It stands as a testament to the potential for harmonising economic and ecological interests, paving the way for a future where sustainability is not just a goal but a foundational principle of energy management. Recycling waste heat not only offers a pathway to substantial energy savings but also embodies a proactive approach to reducing our carbon footprint, echoing the urgent need for sustainable solutions in the face of global climate challenges. Through continuous innovation and a commitment to green energy principles, heat recovery is set to play a pivotal role in the evolution of energy systems, making it an indispensable strategy in our collective journey towards a more sustainable and energy-efficient world.

FAQS

How long does recoup the investment in a heat recovery system take?

The duration to realise a return on investment for a heat recovery system varies based on several parameters, including the scale of energy consumption, the size of the system implemented, and the overall installation expenses. Nonetheless, many organisations report witnessing a return within 1 to 3 years, attributing this to the substantial reductions in energy expenses and enhancements in operational efficiencies that these systems facilitate.

Is it advisable to install heat recovery systems in homes?

Absolutely, heat recovery systems are viable for domestic settings. They enhance not only a residence’s energy efficiency but also significantly improve the quality of indoor air. These systems are especially advantageous in new constructions or refurbishments that deliberately incorporate energy-efficient solutions.

What steps should be taken to select an appropriately sized heat recovery for my enterprise?

Engaging with a professional HVAC engineer or an energy consultant is paramount to ascertain your specific requirements and to receive guidance on the most fitting heat recovery for your situation. The determination of an optimal system will be influenced by factors such as the dimensions of the building, the level of occupancy, and the patterns of energy utilisation, ensuring that your selection is tailored to meet your precise needs.

| Other Good Articles to Read |

| unreal blogs |

| tba blogs |

| all city forums |

| dany blogs |

| refuge blogs |

| the music blogs |

| key forums |

| the big blog theory |

| joe blogs |

| blogs 4 me |

| Blogs Emon |

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |